| Model | Nominal Bore | do | D | K | g1 | b | f | Z-ød | L | L1 | ≈H |

| A47H-16C A47H-25 A47H-40 | 20 | 15 | 105 | 75 | 55 | 16 | 2 | 4-14 | 100 | 85 | 270 |

| 25 | 20 | 115 | 85 | 65 | 16 | 2 | 4-14 | 100 | 85 | 270 | |

| 32 | 25 | 140 | 100 | 78 | 18 | 2 | 4-18 | 115 | 100 | 312 | |

| 40 | 32 | 150 | 110 | 85 | 18 | 3 | 4-18 | 120 | 110 | 320 | |

| 50 | 40 | 165 | 125 | 100 | 20 | 3 | 4-18 | 135 | 120 | 390 | |

| 65 | 50 | 185 | 145 | 120 | 20 | 3 | 4-18 | 140 | 130 | 395 | |

| 80 | 65 | 200 | 160 | 135 | 20 | 3 | 8-18 | 160 | 135 | 400 | |

| 100 | 80 | 220 | 180 | 155 | 22 | 3 | 8-18 | 170 | 160 | 600 | |

| 125 | 100 | 250 | 210 | 185 | 22 | 3 | 8-18 | 190 | 190 | 620 | |

| 150 | 125 | 285 | 240 | 210 | 24 | 3 | 8-23 | 205 | 195 | 625 | |

| 200 | 150 | 340 | 295 | 265 | 26 | 3 | 12-23 | 240 | 230 | 798 | |

| 250 | 200 | 405 | 355 | 320 | 30 | 3 | 12-26 | 350 | 320 | 981 | |

| 300 | 250 | 460 | 410 | 375 | 30 | 4 | 12-26 | 350 | 320 | 1005 | |

| A47H-64 | 20 | 15 | 105 | 75 | 55 | 16 | 2 | 4-14 | 100 | 85 | 270 |

| 25 | 20 | 115 | 85 | 65 | 16 | 2 | 4-14 | 100 | 85 | 270 | |

| 32 | 25 | 140 | 100 | 78 | 18 | 2 | 4-18 | 115 | 100 | 312 | |

| 40 | 32 | 150 | 110 | 85 | 18 | 3 | 4-18 | 120 | 110 | 320 | |

| 50 | 40 | 165 | 125 | 100 | 20 | 3 | 4-18 | 135 | 120 | 390 | |

| 65 | 50 | 185 | 145 | 120 | 22 | 3 | 8-18 | 140 | 130 | 395 | |

| 80 | 65 | 200 | 160 | 135 | 24 | 3 | 8-18 | 160 | 135 | 400 | |

| 100 | 80 | 230 | 190 | 160 | 24 | 3 | 8-23 | 170 | 160 | 600 | |

| 125 | 100 | 270 | 220 | 188 | 28 | 3 | 8-26 | 190 | 190 | 620 | |

| 150 | 125 | 300 | 250 | 218 | 30 | 3 | 8-26 | 205 | 195 | 625 | |

| 200 | 150 | 360 | 310 | 278 | 34 | 3 | 12-26 | 240 | 230 | 798 |

|

Model |

||

|

A48Y |

||

|

Connection type |

2 |

Screw thread |

|

4 |

Flange type |

|

|

structural style |

1 |

Closed and open type |

|

2 |

Closed full swing |

|

|

7 |

Non closed with handle micro Rev. |

|

|

8 |

Not closed with handle full swing type |

|

|

Sealing surface material |

F |

PTFE |

|

Y |

D507 |

|

|

H |

Cemented carbide |

|

|

Size |

DN |

DN15-DN500 |

|

Opening pressure |

Mpa |

xx Mpa |

|

Material type |

1 |

WCB |

|

2 |

CF8 |

|

|

3 |

CF3 |

|

|

4 |

CF8M |

|

|

5 |

CF3M |

|

|

Pressure |

PN10-PN100 |

|

|

150LB-600LB |

||

|

5K-40K |

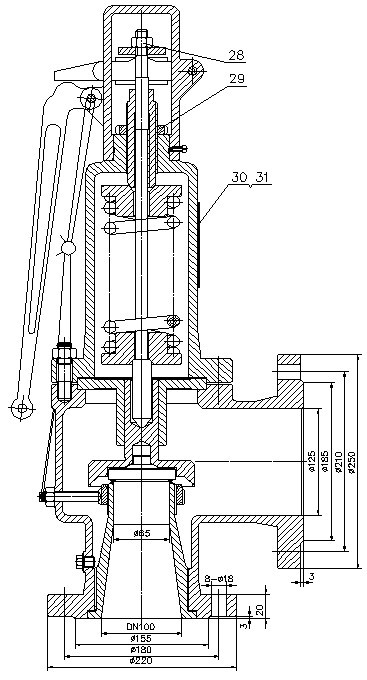

The working principle of spring safety valve

When the pressing force of the steam pressure of safety valve under the flap over the spring, the top valve was opened. Open the top valve, exhaust steam due to the lower ring rebound effect of clamping ring in the valve, the valve opening quickly. Move with the valve, steam impingement in the adjusting ring and the exhaust tends to vertical downward direction, the exhaust steam to generate counterforce to push the valve to and within a certain pressure range enable valve maintained in enough altitude to enhance the safety valve open, steam is continuously discharged, the steam pressure in the system gradually reduce. At this time, will overcome the spring force acting on the valve on the steam pressure and exhaust of the reaction, thereby closing the safety valve.

The structure characteristics of spring safety valve

Spring safety valve from the valve and valve seat sealing surface, valve and valve stem connected to the stem of the total displacement of the valve must meet the requirements from the closed to the open. The setting pressure of the safety valve is adjusted by adjusting the bolt to change the spring pressure. The upper part of the valve is provided with a lever mechanism, which is used for manually lifting the valve stem in the action test. The valve body is provided with an upper and a lower two regulating rings, and the lower part of the regulating ring can be adjusted to obtain a complete take-off action of the valve, and the regulating ring is used to adjust the pressure of the back seat. Back seat pressure is too low, the valve remains open for a longer time; back seat pressure is too high, the valve will continue to take off and shut down, resulting in chatter, resulting in damage to the valve, but also reduce the valve discharge. The optimum position of the upper part of the adjusting ring should be able to make the valve reach full stroke.

Adjust the upper ring and the lower ring

To the right (counterclockwise) move the adjustment ring (guide sleeve), namely increasing regulation loop to reduce safety valve exhaust volume, improve the safety valve back seat pressure; moves to the left on the adjustment ring, that is, to reduce on the adjustment ring, thereby increasing the safety valve emissions, safety valve back seat pressure decreases. On the adjustment ring to adjust the position of the actual change of steam valve of the reaction. The adjustment ring down, then the steam valve to increase the reaction force of the safety valve is not easy to block, then this can reduce the back seat pressure. The adjustment ring must be adjusted with the adjusting ring (nozzle) of the minor adjustment, in order to make the operation of the safety valve is more reliable, sensitive and correct. To the right (counter clockwise) rotation of the adjusting ring, rising to compete the adjustment ring, the valve opens quickly and is very powerful, emissions while increasing the valve; turn left down link, reduce lower adjustment ring, reduce the discharge amount of steam. If the adjusting ring shift position too low, the valve will open and close in a continuous state

Reviews

There are no reviews yet.