Technical parameter

Installation dimensions

Model description

Working Principle

Technical parameter

Structure class | Self contained |

structure type | Bellows balance type, double valve seat balance type, sleeve balance type |

Spool type | Pressure balance type |

Flow characteristics | Fast open, equal percentage, linear |

pressure | 1.6~32MPa, ANSI150~2500, 10K~63K |

Size | DN20~500 |

Applicable temperature | -190~+450℃ |

Leak standard | IV、V、VI class |

Connection type | Flange, thread, welding |

actuator | Pneumatic diaphragm type, piston type |

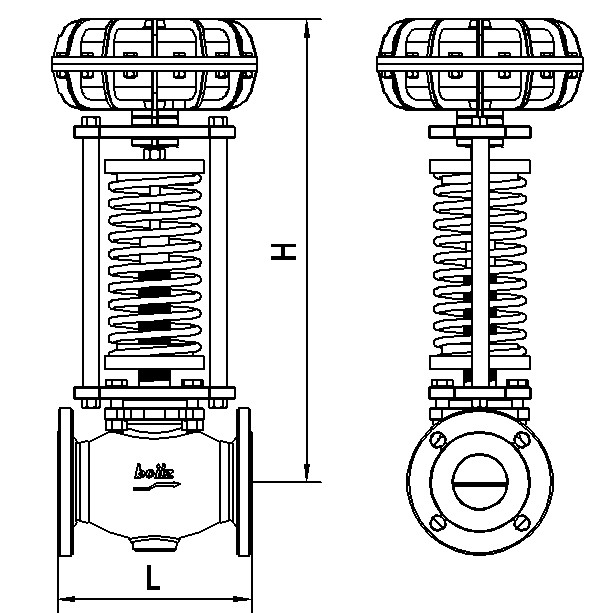

Installation dimensions

- Product structure drawing

- main parameters

DN(mm) 20 25 32 40 50 65 80 100 125 150 200 Rated flow coefficient Kv Large capacity type 7 11 20 30 48 75 120 190 300 480 760 Standard type 5 7 11 20 30 48 75 120 190 300 480 High Accurancy Type 2.8 5 7 11 20 30 48 75 120 190 300 Rated travelL(mm) 8 10 14 20 25 40 50 Pressure PN(Mpa) 1.6 、4.0 、6.4 、10K 、16K 、20K 、ANSI150 、ANSI300 Inherent flow characteristic quick open Inherently adjustable ratioR 30 Set point pressure adjustment range(Kpa) 15~50 40~80 60~100 80~140 120~180 160~220

200~260 240~300 280~350 330~400 380~450

430~500 480~560 540~620 600~700 680~800 780~900

880~1000 950~1500 1000~2500 2000~3000 2500~3500

Adjustment precision(%) Rubber diaphragm:±5 Piston type, metal diaphragm:±10 Maximum operating temperature(℃) -30~185 -30~350 250~560

Model description

| Model | Description | |

| JX331 Self pressure regulating valve | ||

| Actuator | a | diaphragm type |

| b | Piston type | |

| Size | DN | DN15-DN500 |

| upstream pressure | Mpa | xx Mpa |

| downstream pressure | Mpa | xx Mpa |

| Material | 1 | WCB |

| 2 | WC6 | |

| 3 | WC9 | |

| 4 | CF3 | |

| 5 | CF8 | |

| 6 | CF8M | |

| 7 | CF3M | |

| pressure | PN | PN10-PN64 |

Working Principle

- working principlePost valve pressure control Valve front pressure controlWorking medium of the valve before the pressure P1 through the spool, after the throttle valve seat, into the valve after the pressure P2. While P1 through the control line input to the actuator effect on the membrane interior on the top tray, the generated force and the spring reaction force equilibrium determines the relative position of the valve, the valve seat, the control valve before the pressure. When the valve before the pressure P1 increases, the force P1 acting on the top plate also increased. At this point, the top tray force greater than the spring reaction force, the valve core to leave the seat to move in the direction of, until the top plate of the force and the spring reaction force balance so far. At this time, the valve core and the valve seat of the flow area increases, the flow resistance becomes small, so that the P1 down to the set value. Similarly, when the valve before the pressure P1 lower, the role of the direction and the opposite, which is self operated (valve front) pressure regulating valve working principle.Working principle of self operated temperature control valve (heating) Working principle of self operated temperature control valve (cooling type)

- Cooling with self operated temperature control valve works can refer to heating with self operated temperature control valve, only when the valve core component in the implementation of the device and the action of the spring force to open and close off the valve and the temperature contrast, the valve body through the cold medium, mainly used in cooling device of temperature control.

- Temperature control valve is based on the liquid can not be compressed and the principle of expansion and contraction. Heating with self operated temperature control valve, when the controlled object temperature is lower than the set temperature, temperature of liquid contraction, in the implementation of the push rod force decreases, components of the spool under the action of spring force opens the valve to increase the flow of steam and hot oil heating medium, the control object, the temperature rise, until the temperature of the controlled object to the set value, valve is closed, after the valve is closed, controlled object, the temperature drop, the valve open, heating medium and into the heat exchanger, and the temperature rise, so that the temperature of the controlled object to a constant value. The valve opening size is related to the difference between the actual temperature and the set temperature of the controlled object.

- Working medium of the valve before the pressure P1 through the spool, after the throttle valve seat, into the valve after the pressure P2. P2 through the control line input to the actuator chamber under the effect of film in the top tray, the generated force and the spring reaction force equilibrium determines the relative position of the valve, the valve seat control valve pressure. When the valve after the pressure P2 increases, the force P2 acting on the top plate also increased. At this point, the top tray force greater than the spring reaction force, so that the valve is closed to the position of the valve seat, until the top plate of the force and the spring reaction force equilibrium. At this time, the flow area of the valve core and the valve seat is reduced, and the flow resistance becomes large, so that the P2 is reduced to a set value. Similarly, when the valve after the pressure P2 lower, the role of the direction and the opposite, which is self operated (after the valve) pressure regulating valve working principle.

Reviews

There are no reviews yet.